by Mary Crabb

As I had found out when making a replica shell basket from the Museum of English Rural Life (MERL 90/43), processing of cane by hand is a slow and long process (see my previous post). It raised the question of how cane might have been prepared by the makers at Dryad of Leicester for their New Pattern Shell Baskets.

In the early 1900s, cane was used in the manufacture of popular furniture items. During WW1 it was used as a material to weave artillery shell baskets.

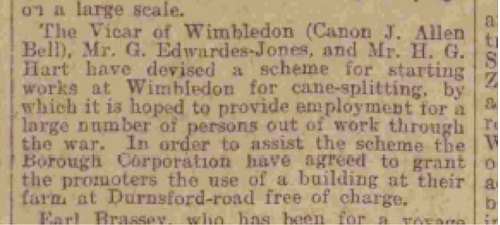

Research at my local reference library in West Sussex enabled me to search through local newspapers of the period using a range of keywords, such as ‘shell’, ‘basket’, ‘willow’ and ‘cane’. I came across a number of useful references, but one in particular from March 1915 relating to cane splitting employment in Wimbledon caught my eye.

West Sussex Gazette, 18th March 1915, p.6e. Acknowledgement to West Sussex County Council Library Service and Johnston Press.

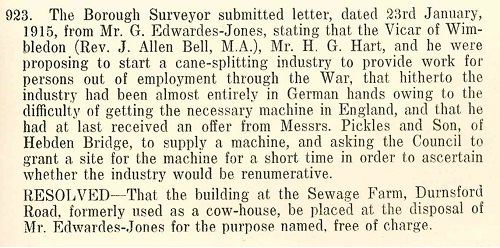

Having discovered some evidence of cane splitting as a process, I decided to follow up the information about the works in Wimbledon by contacting the Merton Heritage Service. Using the date of the newspaper and the names mentioned in the article they found copies of the Borough of Wimbledon Council notes (Highways & Sewerage Committee) from February and April of 1915.

Borough of Wimbledon Council minutes (Highways & Sewerage Committee), 15th February 1915, p.295 para 923. Courtesy of Merton Heritage Service, London Borough of Merton.

The first extract from February 1915 is interesting as it comments that up to this point the industry was based in Germany. Discussion about the necessary machinery required to split the cane confirms that splitting cane was a mechanised process and not something carried out by hand. It also suggests that up until this time it was not normally a process carried out in Great Britain.

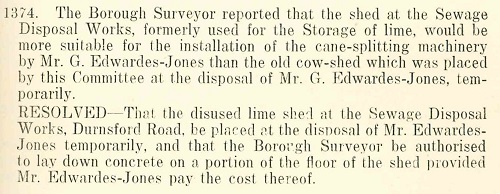

Borough of Wimbledon Council minutes (Highways & Sewerage Committee), 19th April 1915, p.447, para 1374. Courtesy of Merton Heritage Service, London Borough of Merton.

I do not know what happened to the cane splitting works in Wimbledon after the war, but Charles Crampton, one of the four original cane furniture makers at Dryad, comments in the second edition of his book Canework in 1928 (p.8):

“The highest grade of cane splitting is done in Germany and America, but it is also split in France, Holland, Italy, and to a small extent in England.”

This suggests that in 1928, the cane splitting industry in England was still active and worth noting.

Returning to the pre-war years, this film from the archives of the Netherlands Institute for Sound and Vision records the industry in action in Holland in 1913, and shows the stages of processing: sorting, measuring the thickness, cleaving and shaving. These are all processes that I have carried out with the cane I’m using. Whilst I have worked all processes by hand, it would seem that in 1913 the only mechanised parts of the process were cleaving and shaving which, as I have found out, are two of the most crucial elements of the processing.

With thanks to

- Alan Beavon

- West Sussex County Council Library Service and Johnston Press

- Merton Heritage Service, London Borough of Merton